|

Ice Harvesting

Before the 1830's, food was preserved through salting, spicing,

pickling or smoking. Butchers slaughtered meat only for the day's trade, as preservation for longer periods was not practical.

Dairy products and fresh fruits and vegetables subject to spoilage were sold in local markets since storage and shipping farm

produce over any significant distance or time was not practical. Milk was often hauled to city markets at night when temperatures

were cooler. Ale and beer making required cool temperatures, and its manufacture was limited to the cooler months. The solution

to these problems was found in the harvesting of natural ice.

Before the invention of artificial refrigeration in the early twentieth

century, ice was harvested every winter and stored in large ice houses, the proprietors of which sold ice to shippers of fresh

fish, waterfowl, and produce for train deliveries to large cities.

The ice harvesting process was labor intensive, requiring

20-100 men for one to four weeks.

Nineteenth-century ice harvesting began before the actual cutting.

As soon as the ice was strong and thick enough to support horses and equipment, work forces cleared away the insulating snow,

repeatedly if necessary, to encourage the formation of stackable, thicker blocks. When the ice was thick enough, the field

was marked in squares (usually with a horse-drawn marker), scored slightly deeper, and finally the blocks were cut by hand

with the use of large-toothed one-man saws. The blocks were floated to the large adjacent commercial ice house for stacking,

or to a railroad loading ramp for shipping. The system proved workable and lasted throughout the century, the major change

being the late introduction of rotary saws that would replace hand-cutting.

The latter half of the 19th century was filled with attempts to perfect manufactured ice methods.

The Louisiana Ice Manufacturing Company (1868) appears to have been the first one to operate regularly, one of its claims

being a price considerably lower than that of natural ice. Others followed. By 1925 factory-made ice had entered the realm

of big business, and natural ice had become a thing of the past.

Ice Houses

From the 17th century, the rich and privileged increasingly

built ice houses in the grounds of their large houses in the country, and occasionally within town houses to preserve food

and provide ice for the table and especially to cool wine.

In the 19th century commercial ice houses were constructed

to provide ice for general use, to stock private ice houses when supplies from the local pool were scarce and later to produce

“frozen” food.

Some ice house's were really a barn within a barn, with 3 feet of sawdust and hay between the inner and outer walls.

Misc. Ice Facts

The Chinese cut and stored ice in 1,000 B.C.

Around 500 B.C. the Egyptians and Indians made ice on cold

nights by setting water out in earthenware pots and keeping the pots wet.

In 18th century England, servants collected ice in the winter

and put it into icehouses, where the sheets of ice were packed in salt, wrapped in strips of flannel, and stored underground

to keep them frozen until summer.

At the beginning of the 19th century, ice boxes were used in

England

Natural ice was harvested, distributed

and used in both commercial and home applications in the mid-1800s. The ice trade between Boston and the South was one of

the first casualties of the Civil War.

City dwellers had ice delivered to them by horse and wagon.

The iceman had to lift from 25- to 100-pound blocks, according to the order, which was placed by the consumer putting a numbered

card in the window that corresponded with the number of pounds of ice they wanted (25,50,75,100). The ice was weighed on a

spring scale on the truck, but an experienced delivery man could estimate the weight. The ice was carried to a kitchen using

ice tongs, and chipped with chisels to fit the compartment of the ice box.

Delivery men were known for their brawn, as they hauled heavy blocks of ice all day long, and

often up flights of stairs. They often had access to the kitchen when no one was home, and they simply placed the ice appropriately.

Some city apartments used a suspended box (a small version of the ice box) outside the kitchen window, its contents available

to the cook through the raised window; others kept an ice chest outdoors on the porch, or a handsome oak refrigerator in the

kitchen. Ice wagons were the delight of children playing in summer’s heat; it was a good day when the iceman dropped

his ice tongs and used his ice pick to chop a small piece of ice for someone to suck on.

|

| A sinking Ice Truck!! |

With

ice so plentiful, changing culinary fashion exploited it in all kinds of chilled and frozen desserts. In 1914 Linda Hull Larned

published a cookbook entirely devoted to the new ice-centered genre, a small volume entitled One Hundred Cold Desserts. Her

direction, in Sponge and Fruit Cake Cream (English Trifle), to put the dessert “on ice” was understood literally.

There were more and more uses for ice, and more spin-off equipment. The 1904 World’s Fair (St. Louis) introduced iced

tea; a number of different ice cream makers for home use were marketed in the latter 1800s, probably the most famous being

the White Mountain hand-crank bucket style.

Ice was the second largest

export from the U.S. in the 19th century (Cotton was #1).

Ice Boxes

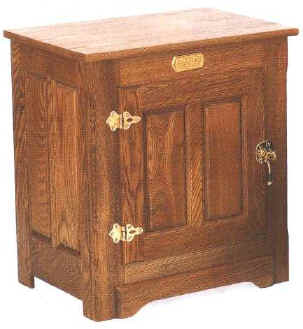

Residential ice boxes, many home-made, were of oak, pine, or ash wood

lined with zinc, slate, porcelain, galvanized metal or wood. The insulator between the walls was charcoal, cork, flax straw

or mineral wool. Still, the ice lasted only one day.

Wooden boxes lined with tin or zinc and insulated with various materials including

cork, sawdust, and seaweed were used to hold blocks of ice and "refrigerate" food. A drip pan collected the melt water - and

had to be emptied daily.

Electric refrigerators and freezers would seriously hurt

the ice industry. Although the first models were marketed before 1920, it would be a while before everyone had them, and ice

therefore continued in use, although decreasingly.

Tools

Early tools for ice cutting were the ax, the scraper, the ice

saw, and the breaking off bar. After 1900, the horse-drawn ice marker and ice plow came into use. By 1918, the power field

saw was introduced.

Other tools:

Grapple or ice hook towed sheets of ice along channels and

hauled blocks up the chute.

Scoop net cleaned channels.

Breaking off bar (similar to a crowbar) was used to detach

sheets from the field of ice.

|